Understanding low voltage compositions: a comprehensive guide

Low voltage systems refer to electrical systems that operate at voltages below a certain threshold, typically recognized as under 1000 volts in alternating current (AC) and under 1500 volts in direct current (DC). These systems are crucial for the safe and efficient operation of a wide range of industrial equipment, particularly in sectors like woodworking where precision and reliability are paramount.

Within industrial settings, low voltage compositions are integral to the operation of machinery, lighting, heating, and ventilation systems. They are also essential in automation and control processes, which are increasingly important for enhancing productivity and maintaining competitive advantage.

Components of Low Voltage Compositions

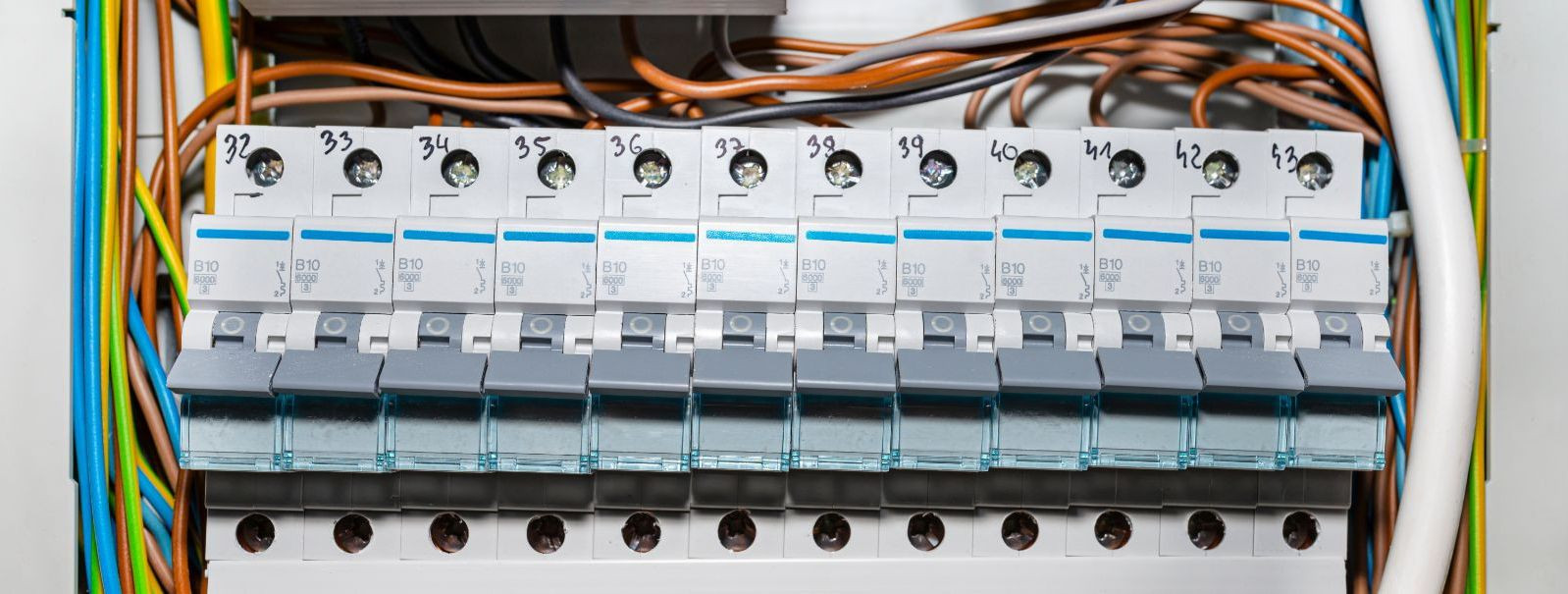

Switchgear is the combination of electrical disconnect switches, fuses, or circuit breakers used to control, protect, and isolate electrical equipment. It's a vital component in managing power distribution and ensuring safety within low voltage systems.

Control panels house the electrical controls for machines, while distribution boards divide an electrical power feed into subsidiary circuits. Both are key in distributing power effectively and facilitating easy control over multiple power circuits.

Protection devices such as circuit breakers and fuses safeguard electrical circuits from damage caused by overcurrent, overload, or short circuit. They are essential for preventing equipment failure and ensuring personnel safety.

The selection of appropriate cabling and accessories is critical for the reliability of low voltage systems. This includes choosing the right type and size of cables, conduits, connectors, and fittings to ensure secure and efficient power distribution.

Design Considerations for Low Voltage Systems

Accurate load assessment is the foundation of designing an effective low voltage system. It involves calculating the total power requirements and planning the system layout to accommodate current and future needs.

Selecting the right components for a low voltage system is a complex task that requires a deep understanding of the equipment's operational demands and the environmental conditions of the industrial setting.

Compliance with national and international electrical standards is non-negotiable. It ensures that low voltage systems are safe, reliable, and capable of meeting the rigorous demands of industrial operations.

Installation and Maintenance of Low Voltage Systems

Proper installation of low voltage systems is critical for their performance and longevity. This includes following best practices such as correct wiring techniques, secure mounting of components, and thorough testing before commissioning.

Regular maintenance is essential to prevent downtime and extend the life of low voltage systems. This includes routine inspections, cleaning, and testing of components to ensure they are functioning correctly.

Understanding how to troubleshoot common issues in low voltage systems can save time and reduce the risk of prolonged outages. Familiarity with the system and its components is key to diagnosing and resolving problems quickly.

Advancements in Low Voltage Technology

The continuous development of low voltage components, such as more compact and efficient switchgear, contributes to the evolution of industrial electrical systems.

Integration of smart technologies and automation in low voltage systems is transforming the way industries operate. These advancements enable real-time monitoring, predictive maintenance, and enhanced control over electrical systems.

Modern low voltage systems are increasingly designed with a focus on energy efficiency and sustainability. This not only reduces operational costs but also supports environmental initiatives.

Comments (0)