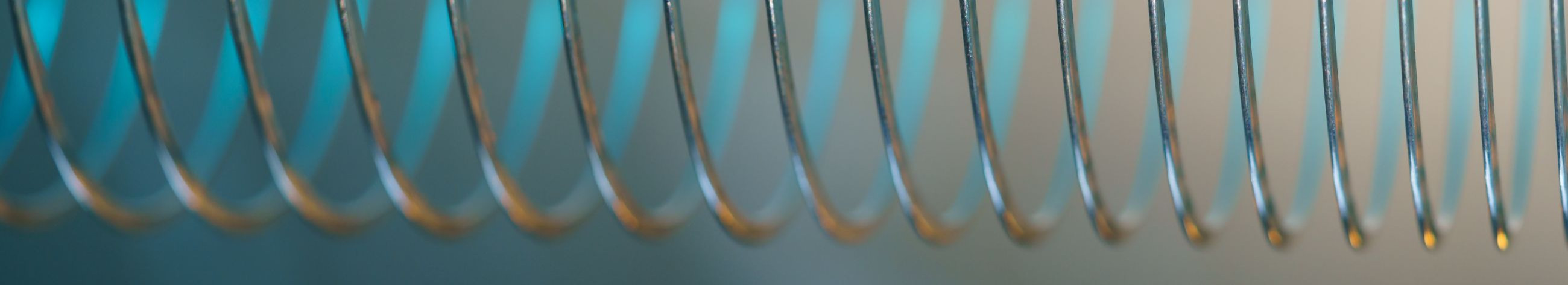

The ultimate guide to choosing the right metal staples for your project

Metal staples are a ubiquitous component in numerous industries, serving as a simple yet essential fastening solution. From securing roofing materials in construction to assembling components in automotive manufacturing, the right metal staple can be the linchpin of a project's success.

There are various types of metal staples, each designed for specific tasks. These include fine wire staples, heavy-duty staples, carton-closing staples, and more, each with unique attributes tailored to different applications.

Factors to Consider When Selecting Metal Staples

The material of a staple affects its performance and suitability for a project. Common materials include stainless steel, galvanized steel, and aluminum, each offering different levels of strength and resistance to environmental factors.

The size and gauge of a staple determine its holding power and compatibility with materials. It's crucial to select the correct gauge to ensure the staple can penetrate and hold the materials without causing damage.

The leg length and crown width of a staple must be appropriate for the thickness and type of material being fastened. A mismatch can lead to insecure fastening or material damage.

Ensuring that the staples are compatible with the tools and machinery used for application is vital for efficient and safe operations.

For projects exposed to harsh environments, selecting staples with high corrosion resistance is essential to prevent weakening over time.

The strength and durability of metal staples are paramount, especially in applications where structural integrity is critical.

Industry-Specific Requirements

In these precision-driven industries, staples must meet stringent standards for strength and reliability, often requiring custom solutions.

For construction, staples must support heavy loads and withstand environmental stress, making material choice and design crucial.

Staples used in manufacturing must be consistent in quality to maintain production efficiency and product integrity.

Packaging staples need to secure materials effectively while also being safe for end-users to handle.

Custom Solutions from VEDRUMET OÜ

VEDRUMET OÜ specializes in creating custom metal staples tailored to specific industry needs, ensuring optimal performance for any project.

Our rigorous quality assurance and testing processes guarantee that every staple meets the highest standards of durability and reliability.

We provide comprehensive supply chain solutions to ensure timely delivery of staples, helping clients maintain their production schedules.

Comments (0)