The art of cnc turning: transforming metal into precision components

CNC turning is a manufacturing process where computer-controlled machines shape metal or plastic materials into precise components. It's a subtractive process, meaning it removes material to create the desired shape. This technique is crucial for industries that demand high precision and repeatability in their parts.

From manual lathes to the advanced CNC machines of today, the evolution of turning technology has been driven by the need for more precise, efficient, and complex component production. CNC turning machines now come equipped with sophisticated software, allowing for intricate designs and tight tolerances.

The CNC Turning Process

The first step in CNC turning is creating a detailed design using CAD software. This design is then translated into a program using CAM software, which the CNC machine will use to execute the turning operation.

Choosing the right material is critical for the success of the final component. Factors such as the part's application, required strength, and thermal properties influence this choice.

Before the turning process begins, the CNC lathe must be properly set up. This includes installing the correct tools and fixtures, and calibrating the machine for optimal performance.

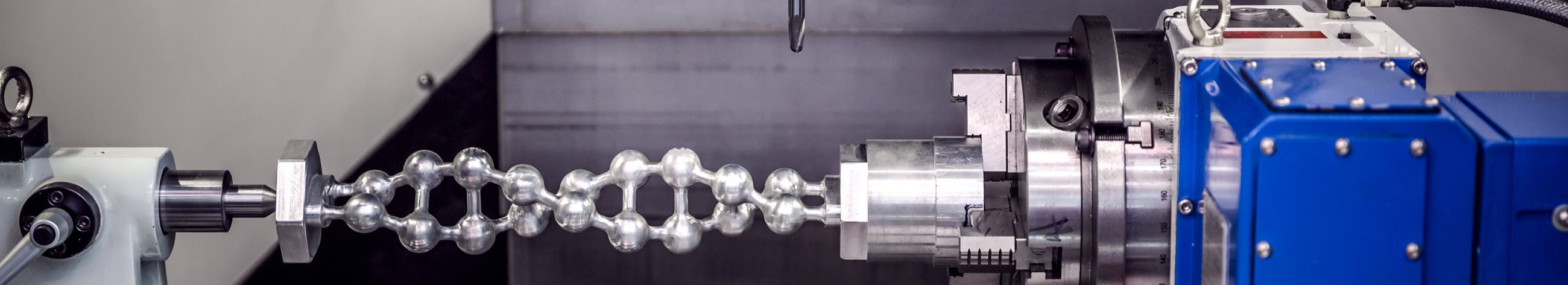

During the turning operation, the workpiece is rotated while a cutting tool is moved across it in a controlled manner. This process can create a variety of shapes, from simple cylinders to complex geometrical components.

Quality control is integral to CNC turning. Measurements and inspections ensure that each component meets the required specifications. Post-processing may include additional treatments like polishing or anodizing.

Advantages of CNC Turning

CNC turning is renowned for its ability to produce parts with exceptional precision and accuracy, which is essential for many high-tech industries.

With CNC turning, parts can be produced much faster than with manual machining, leading to shorter lead times and increased productivity.

The process is suitable for a wide range of materials and can easily accommodate changes in design, making it ideal for both prototyping and production runs.

Although the initial setup cost may be higher, the efficiency and reduced labor costs associated with CNC turning make it a cost-effective solution in the long run.

Applications of CNC Turned Components

CNC turned parts are essential in the automotive industry, where they are used in engines, transmissions, and other critical systems.

The aerospace and defense sectors rely on CNC turning for components that must meet stringent quality and precision standards.

Medical device manufacturers use CNC turning to create components that are safe, reliable, and meet the industry's strict regulatory requirements.

From smartphones to home appliances, CNC turned parts are found in a variety of consumer electronics, where they contribute to the devices' functionality and durability.

Choosing the Right CNC Turning Partner

When selecting a CNC turning partner, it's important to consider their expertise and experience in the industry to ensure they can meet your specific needs.

A reliable partner should have robust quality assurance processes in place to deliver consistently high-quality components.

Effective communication and customer service are key to a successful partnership, ensuring that your project requirements are fully understood and met.

Finally, the partner's capacity and capabilities should align with your project's scale and complexity to guarantee timely delivery and performance.

Discover unparalleled precision and expertise with MILLPAK OÜ's CNC turning services. Contact us to elevate your manufacturing to the next level.

Comments (0)