5 reasons why cnc milling is essential for modern manufacturing

CNC milling stands as a cornerstone in modern manufacturing, offering unparalleled precision, versatility, and efficiency. As a process that utilizes computer-controlled machine tools to remove material from a workpiece, CNC milling has revolutionized the way we produce everything from simple parts to complex components. In this post, we'll explore five key reasons why CNC milling is indispensable for today's manufacturing landscape.

1. Precision and Consistency

CNC milling machines are renowned for their ability to produce parts with extremely tight tolerances. The precision of CNC equipment ensures that each component meets stringent specifications, which is critical for industries where precision is non-negotiable, such as aerospace and medical device manufacturing.

Not only does CNC milling deliver precision, but it also offers consistent repeatability. This means that whether you're producing a single prototype or a high volume of parts, each piece will match the original design with exacting accuracy, time after time.

2. Versatility and Flexibility

CNC milling machines can work with a wide range of materials, from metals like aluminum and steel to plastics and composites. This material versatility makes CNC milling a go-to solution for various industries, accommodating the diverse needs of product manufacturing.

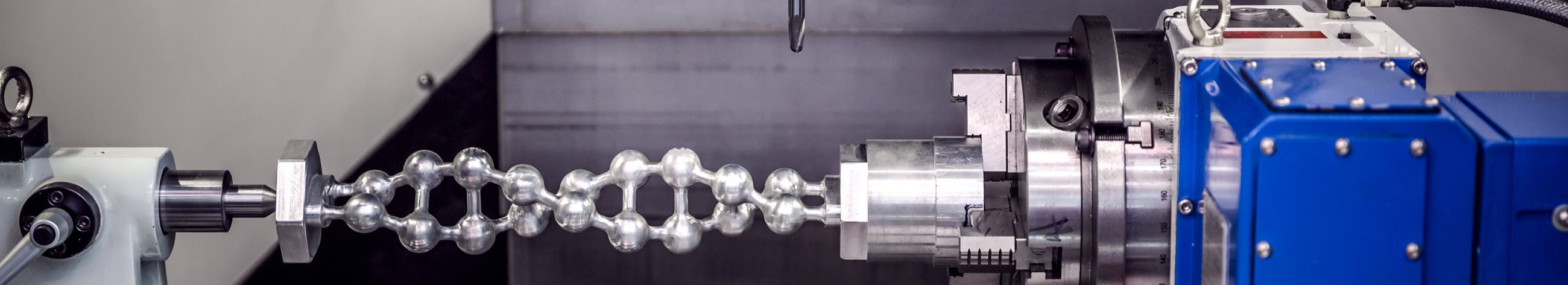

The advanced capabilities of CNC milling machines allow for the creation of parts with complex geometries that would be difficult or impossible to achieve with manual machining. This opens up possibilities for innovative design and functionality in manufactured products.

3. Efficiency and Speed

With CNC milling, the time from design to production is significantly reduced. The digital nature of CNC programming allows for quick setup and changeovers, leading to shorter lead times and faster time-to-market for new products.

CNC milling machines are capable of operating at high speeds without sacrificing quality. This high-speed machining translates to more parts produced in less time, boosting overall productivity.

4. Integration with Modern Technologies

The integration of advanced software in CNC milling not only simplifies the machining process but also enhances the capabilities of what can be achieved. From complex CAD/CAM software to simulation and verification tools, these technologies ensure that CNC milling remains at the forefront of manufacturing innovation.

The use of automation and robotics in conjunction with CNC milling machines further increases efficiency and productivity. Automated tool changers, robotic loading and unloading, and lights-out manufacturing are just a few examples of how CNC milling is integrated with cutting-edge technologies to stay competitive.

5. Cost-Effectiveness

CNC milling is a subtractive manufacturing process that maximizes material utilization, leading to less waste and more cost-effective production. The precision of CNC milling also means fewer errors and less scrap, contributing to a more sustainable manufacturing approach.

While the upfront investment in CNC milling equipment may be significant, the reduction in labor costs over time can lead to substantial savings. CNC machines require less manual intervention, allowing skilled workers to focus on other critical tasks and reducing the overall labor required for production.

Discover unparalleled precision and efficiency with MILLPAK OÜ's CNC milling services. Contact us to elevate your manufacturing process.

Comments (0)