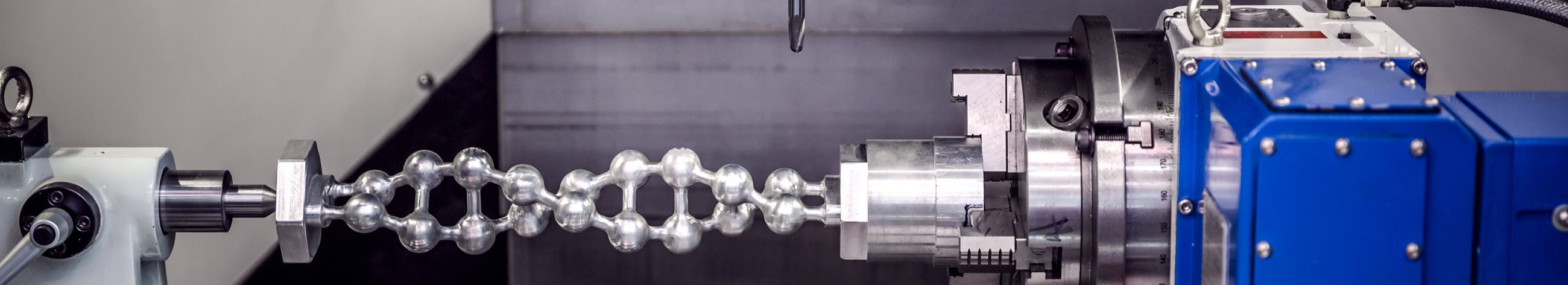

Understanding the materials: a guide to metal and plastic for cnc work

Choosing the right material for CNC machining is crucial for the success of any project. The material not only influences the performance and longevity of the final product but also affects the machining process itself. This guide will delve into the most common metals and plastics used in CNC work, their properties, and how to select the appropriate material for your specific needs.

Metals for CNC Machining

Aluminum is lightweight, has excellent machinability, and offers good strength-to-weight ratio. It's ideal for aerospace, automotive, and consumer electronics applications.

Known for its corrosion resistance, stainless steel is a go-to for medical devices, food processing equipment, and marine applications.

Brass is easy to machine and has a pleasing aesthetic, making it suitable for decorative items, musical instruments, and fittings.

Titanium boasts high strength, low weight, and excellent corrosion resistance, perfect for aerospace and medical implants.

Copper is known for its thermal and electrical conductivity, commonly used in electrical components and heat exchangers.

Plastics for CNC Machining

ABS is a versatile plastic with good mechanical properties, impact resistance, and is easy to machine. It's widely used in automotive parts, consumer goods, and enclosures.

Polycarbonate is known for its strength, toughness, and transparency, making it ideal for protective gear, windows, and lenses.

PEEK is a high-performance plastic with exceptional thermal stability, chemical resistance, and mechanical properties, suited for demanding applications like aerospace and medical devices.

Nylon is durable, has high wear resistance, and is used in gears, bearings, and industrial components.

Acetal offers high stiffness, low friction, and excellent dimensional stability, perfect for precision parts in mechanical assemblies.

Factors Influencing Material Choice

The required strength and durability of the final product are paramount when selecting a material for CNC machining.

Materials with the right thermal properties are essential for components that will be exposed to high temperatures or require insulation.

For parts that will come into contact with aggressive chemicals, materials with high chemical resistance are necessary.

While the material performance is critical, cost is also a significant factor in the selection process.

The desired surface finish and aesthetics of the final product can also influence the choice of material.

Material Properties and CNC Machining Capabilities

Materials with high machinability allow for faster production and lower costs.

Dimensional stability is crucial for precision parts, as it ensures the component maintains its shape during and after machining.

Different materials may require specific tooling, which can affect the overall machining process.

Choosing the Right Material for Your Project

Knowing the application and environment in which the part will operate is essential for material selection.

The stage of development—whether prototyping or full-scale production—can influence the choice of material.

Working with experienced professionals can help you navigate the complexities of material selection for CNC machining.

Seeking precision CNC milling and turning services? Contact MILLPAK OÜ for expert guidance on selecting the right materials for your project.

Comments (0)