Top 5 signs your factory machinery needs repair

In the fast-paced world of industrial manufacturing, the efficiency and reliability of factory machinery are paramount. Regular maintenance and timely repairs are crucial to ensure that operations run smoothly, minimizing downtime and maximizing productivity. However, identifying when your machinery needs repair can be challenging. Here, we outline the top five signs that indicate your factory machinery may require attention.

Sign 1: Unusual Noises

Factory machinery is inherently noisy, but experienced operators can often distinguish between normal operational sounds and those that signal trouble. Unusual noises such as grinding, squealing, or knocking can be early indicators of mechanical issues.

These noises may result from misaligned components, worn-out bearings, or insufficient lubrication. Ignoring these sounds can lead to more severe damage, resulting in costly repairs or even complete machinery failure.

Sign 2: Decreased Performance

When machinery begins to underperform, it can manifest as slower production rates, inconsistent product quality, or increased cycle times. These symptoms often indicate underlying mechanical problems.

Decreased performance not only affects your production schedule but also increases operational costs. Identifying and addressing the root cause of the inefficiency can prevent further financial losses.

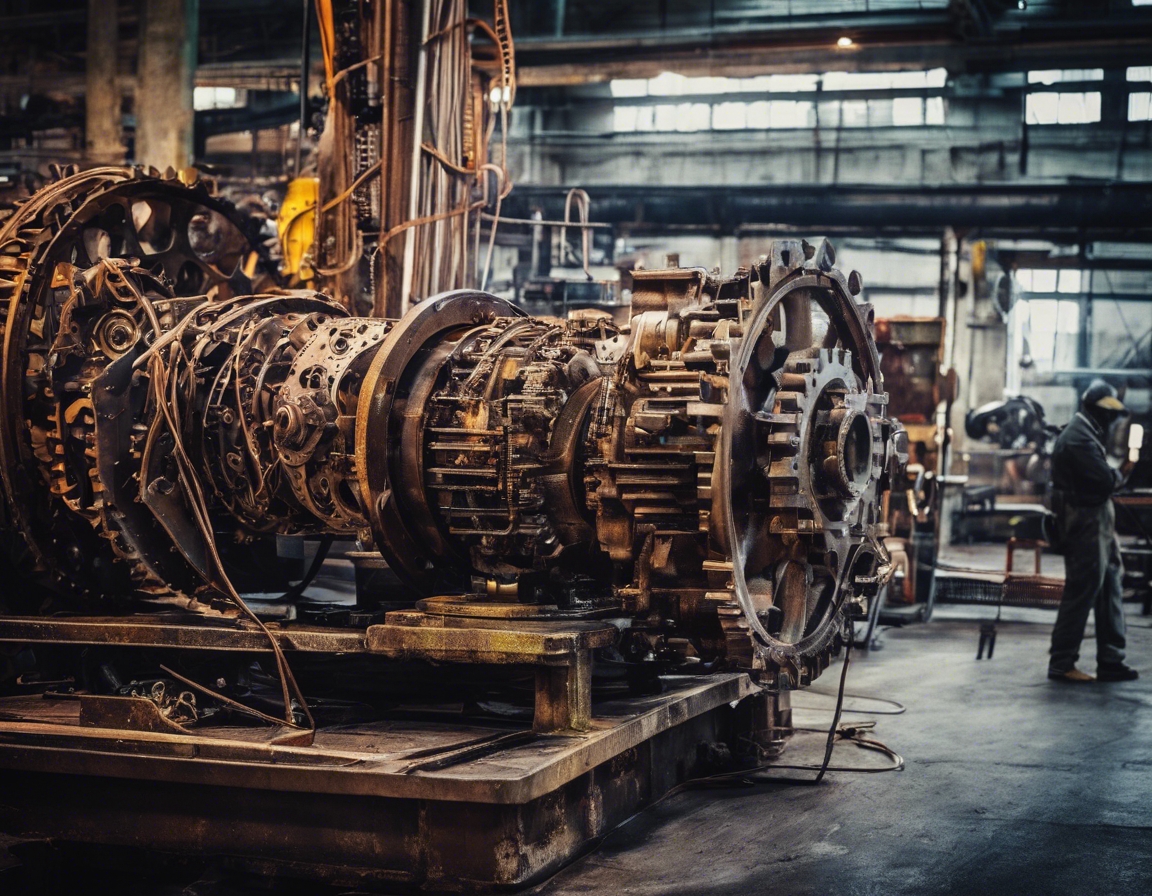

Sign 3: Visible Wear and Tear

Regular inspections can reveal visible signs of wear and tear, such as cracks, rust, or worn-out parts. These signs are often precursors to more significant issues if not addressed promptly.

Conducting routine visual inspections and using diagnostic tools can help identify wear early. This proactive approach allows for timely repairs, extending the lifespan of your machinery.

Sign 4: Increased Energy Consumption

Sudden spikes in energy consumption can be a red flag for machinery problems. Monitoring energy usage patterns can help detect inefficiencies that may require repair.

Increased energy consumption often correlates with mechanical issues such as motor inefficiencies or electrical faults. Addressing these issues can lead to significant energy savings and improved operational efficiency.

Sign 5: Frequent Breakdowns

Frequent machinery breakdowns disrupt production and can indicate deeper mechanical problems. Identifying patterns in these breakdowns can help pinpoint the underlying issues.

Repeated breakdowns not only affect immediate production but can also lead to long-term operational challenges, including increased maintenance costs and reduced equipment lifespan.

Importance of Timely Repairs

Timely repairs prevent minor issues from escalating into major problems, ensuring that your machinery operates efficiently and reliably. This proactive approach minimizes downtime and extends the life of your equipment.

Neglecting necessary repairs can lead to catastrophic machinery failures, resulting in significant financial losses and safety hazards. Prioritizing maintenance and repairs is essential for maintaining a safe and productive work environment.

Comments (0)