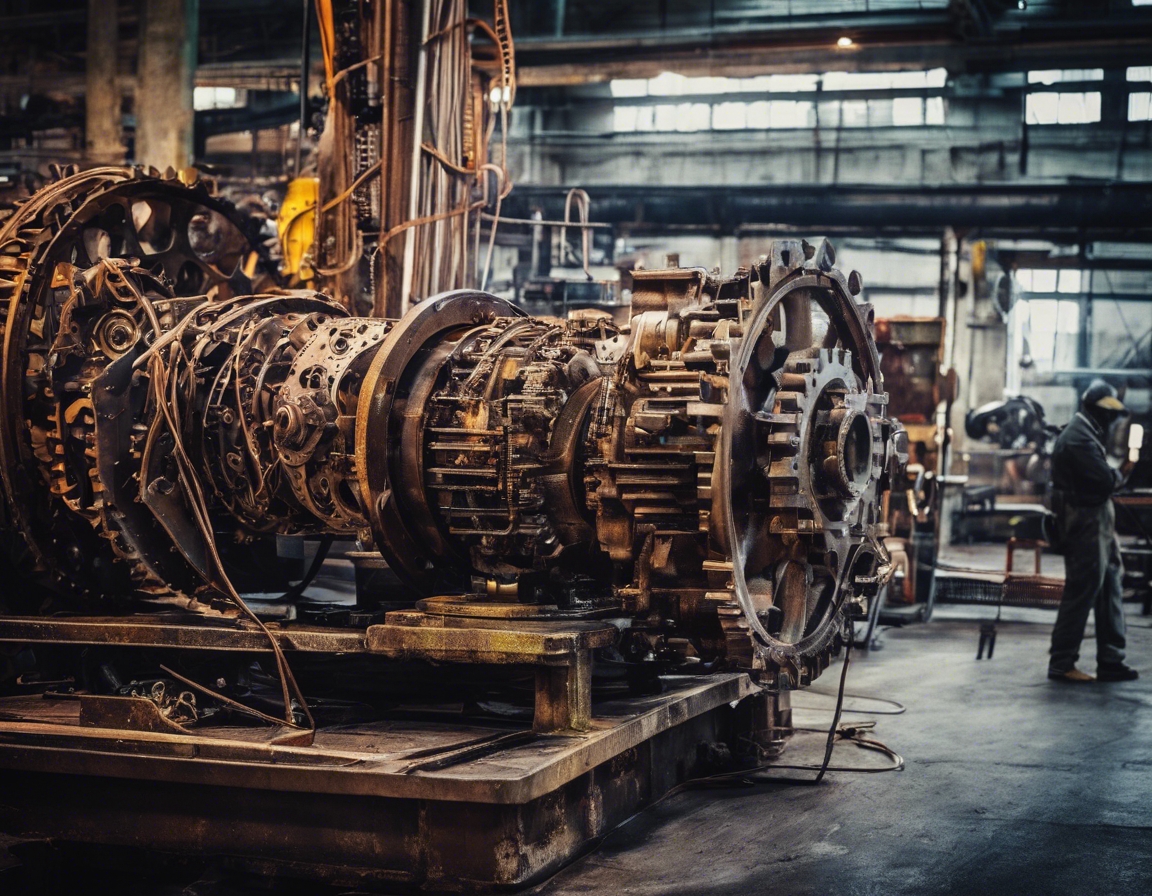

Top tips for reducing machinery downtime

In the fast-paced world of industrial manufacturing, machinery downtime can be a significant obstacle to achieving optimal productivity and efficiency. Downtime not only affects production schedules but also incurs substantial costs, impacting the bottom line. Understanding and mitigating the factors that contribute to machinery downtime is crucial for manufacturers and factory operators aiming to maintain seamless operations.

Understanding the Causes of Downtime

Equipment failure is one of the most common causes of downtime. This can result from wear and tear, lack of maintenance, or unexpected breakdowns. Regular inspections and timely repairs are essential to prevent equipment from failing during critical production periods.

Human error can lead to machinery downtime through improper operation, incorrect setup, or failure to follow standard operating procedures. Ensuring that staff are well-trained and adhere to protocols can significantly reduce the risk of downtime caused by human mistakes.

Inadequate or irregular maintenance can lead to machinery breakdowns. A well-structured maintenance schedule that includes both preventive and predictive maintenance can help in identifying potential issues before they result in downtime.

Delays in the supply chain can halt production if essential parts or materials are not available when needed. Effective supply chain management and having contingency plans in place can mitigate these disruptions.

Strategies for Reducing Downtime

Preventive maintenance involves regular and systematic inspection, cleaning, and replacement of worn parts to prevent unexpected machinery failures. This proactive approach can extend the lifespan of equipment and reduce the likelihood of downtime.

Continuous training and development programs for employees ensure that they are equipped with the necessary skills and knowledge to operate machinery efficiently. This reduces the chances of human error and enhances overall productivity.

Predictive maintenance uses advanced technologies such as IoT sensors and data analytics to monitor equipment conditions in real-time. By predicting potential failures before they occur, manufacturers can schedule maintenance activities at the most convenient times, minimizing downtime.

Optimizing supply chain processes ensures that materials and parts are available when needed, reducing the risk of production delays. Building strong relationships with suppliers and using inventory management software can enhance supply chain efficiency.

Monitoring and Analyzing Downtime

Downtime tracking software provides valuable insights into the frequency and causes of downtime. By collecting and analyzing this data, manufacturers can identify patterns and implement targeted strategies to reduce downtime.

Regular analysis of downtime data allows manufacturers to make informed decisions and continuously improve their processes. By understanding the root causes of downtime, companies can implement effective solutions and enhance overall operational efficiency.

Comments (0)