The art of manual wire manufacturing

Wire is a fundamental component in countless applications across the automotive, aerospace, and electronics sectors. Its versatility and functionality make it indispensable in the modern industrial landscape. From transmitting power and signals to forming the backbone of complex assemblies, wire is the unsung hero of technological advancements.

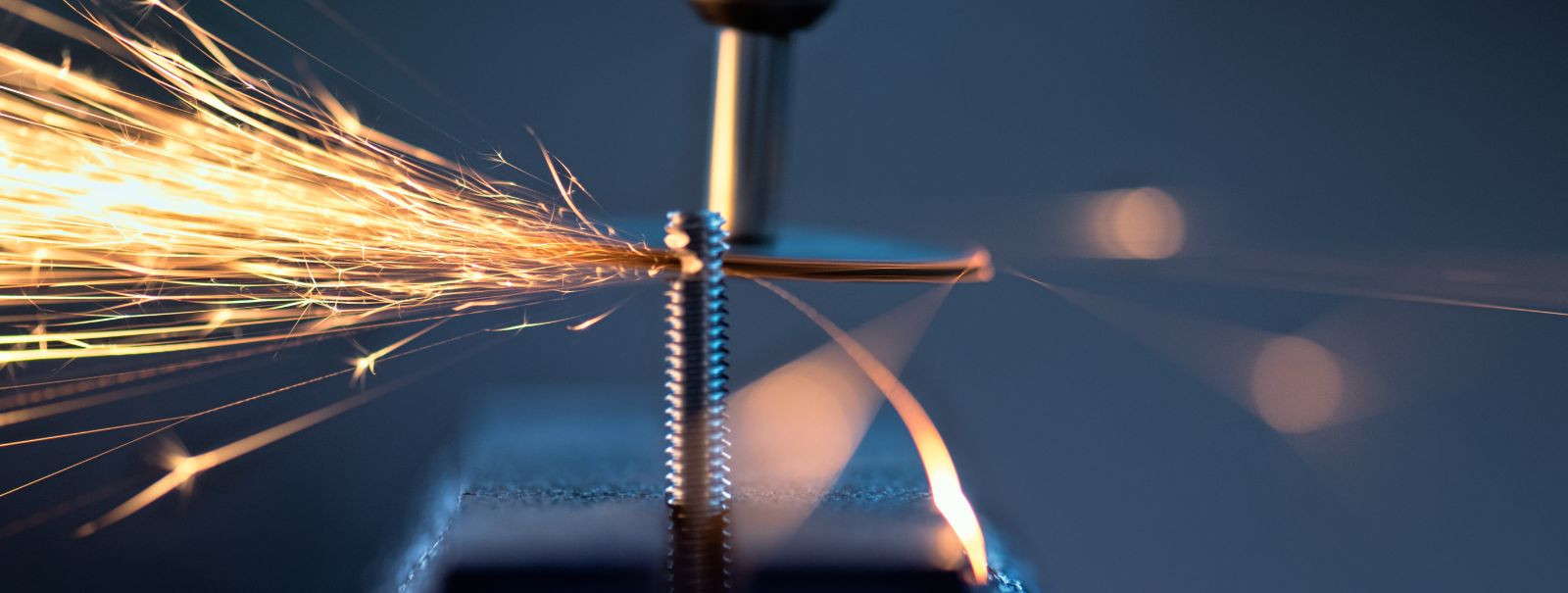

Manual wire manufacturing is the traditional process of creating wire through hands-on techniques and machinery. It involves a series of steps that transform raw materials into precise wire products tailored to specific industry needs. This artisanal approach allows for a high degree of customization and quality control, setting it apart from mass-produced alternatives.

The Manual Wire Manufacturing Process

Choosing the right material is the first critical step in manual wire manufacturing. Materials range from copper and aluminum to high-strength alloys, each selected based on the wire's intended use. KOMPONENT OÜ prides itself on sourcing premium materials to ensure the final product meets the highest standards of conductivity, durability, and performance.

The wire drawing process involves pulling the chosen material through a series of dies to reduce its diameter to the desired size. This requires precision and skill to maintain the integrity of the wire while achieving the necessary specifications.

Stranding combines individual wire strands to form a conductor, while cabling intertwines these conductors to create a robust and flexible cable. These processes are crucial for producing wire that can withstand bending and twisting without compromising its structural integrity.

Insulation and sheathing are applied to protect the wire from environmental factors and electrical interference. The choice of materials and application methods are tailored to the wire's application, ensuring optimal performance in its operating environment.

Each step of the manual wire manufacturing process is accompanied by stringent quality control measures. KOMPONENT OÜ conducts thorough testing to verify that the wire meets all industry standards and customer specifications before it leaves the facility.

Customization in Manual Wire Manufacturing

One of the key advantages of manual wire manufacturing is the ability to produce custom wire configurations. Clients can specify the wire's properties, such as gauge, insulation type, and conductor material, to perfectly suit their unique applications.

Material customization allows clients to choose materials that offer the best balance of electrical properties, strength, and flexibility for their specific needs. KOMPONENT OÜ's expertise in material science ensures that each wire is optimized for its intended use.

Designing wire for specific applications involves considering factors such as temperature range, mechanical stress, and exposure to chemicals. KOMPONENT OÜ works closely with clients to develop wires that meet the exact requirements of their projects.

The Benefits of Manual Wire Manufacturing

Manual wire manufacturing yields products of exceptional quality and reliability. The hands-on approach allows for meticulous attention to detail, resulting in wire that consistently performs at the highest level.

The flexibility of manual wire manufacturing means that small batches and custom orders can be accommodated without sacrificing quality. This is particularly beneficial for small businesses and entrepreneurs who require specialized wire solutions.

Without the constraints of large-scale production schedules, manual wire manufacturing can often offer shorter lead times. This is crucial for clients who need to minimize downtime and accelerate project timelines.

Why Choose KOMPONENT OÜ for Your Wire Manufacturing Needs

With over two decades of experience, KOMPONENT OÜ has honed the craft of manual wire manufacturing to perfection. The company's skilled technicians are adept at creating high-quality wire products that meet the exacting demands of modern industries.

KOMPONENT OÜ's unwavering commitment to quality is evident in every wire they produce. From material selection to final inspection, each step is executed with precision and care.

Understanding that each client has unique needs, KOMPONENT OÜ adopts a customer-centric approach to wire manufacturing. The company collaborates closely with clients to ensure their requirements are met and their expectations exceeded.

Comments (0)