5 ways 3d modeling is transforming the design process

The advent of 3D modeling has revolutionized the design process across various industries. By creating detailed digital representations of objects, 3D modeling allows for a more nuanced and comprehensive approach to design. This transformative technology has become an indispensable tool for engineers, designers, architects, and manufacturers who seek to innovate and stay competitive in a rapidly evolving market.

1. Enhanced Visualization and Communication

3D modeling software enables the creation of highly realistic renderings and virtual prototypes that provide a vivid glimpse into the final product. This allows designers to explore ideas and concepts with an unprecedented level of detail, making it easier to identify potential issues and improvements early in the design process.

With 3D models, clients can visualize the end product more effectively, leading to better communication and collaboration. This enhanced interaction ensures that client feedback is accurately incorporated, resulting in designs that truly meet their needs and expectations.

2. Streamlined Design Iterations

Designers can quickly modify 3D models, saving time and resources that would otherwise be spent on creating new prototypes. Version control is also simplified, as changes can be tracked and managed with ease, ensuring that everyone involved in the project is working with the most up-to-date information.

The ability to make rapid changes to 3D models not only accelerates the design process but also significantly reduces the costs associated with physical prototyping and testing.

3. Integration with Advanced Technologies

3D models are easily integrated with VR and AR technologies, providing immersive experiences that can enhance design review, client presentations, and even user testing. This integration opens up new possibilities for interactive design and helps stakeholders better understand complex projects.

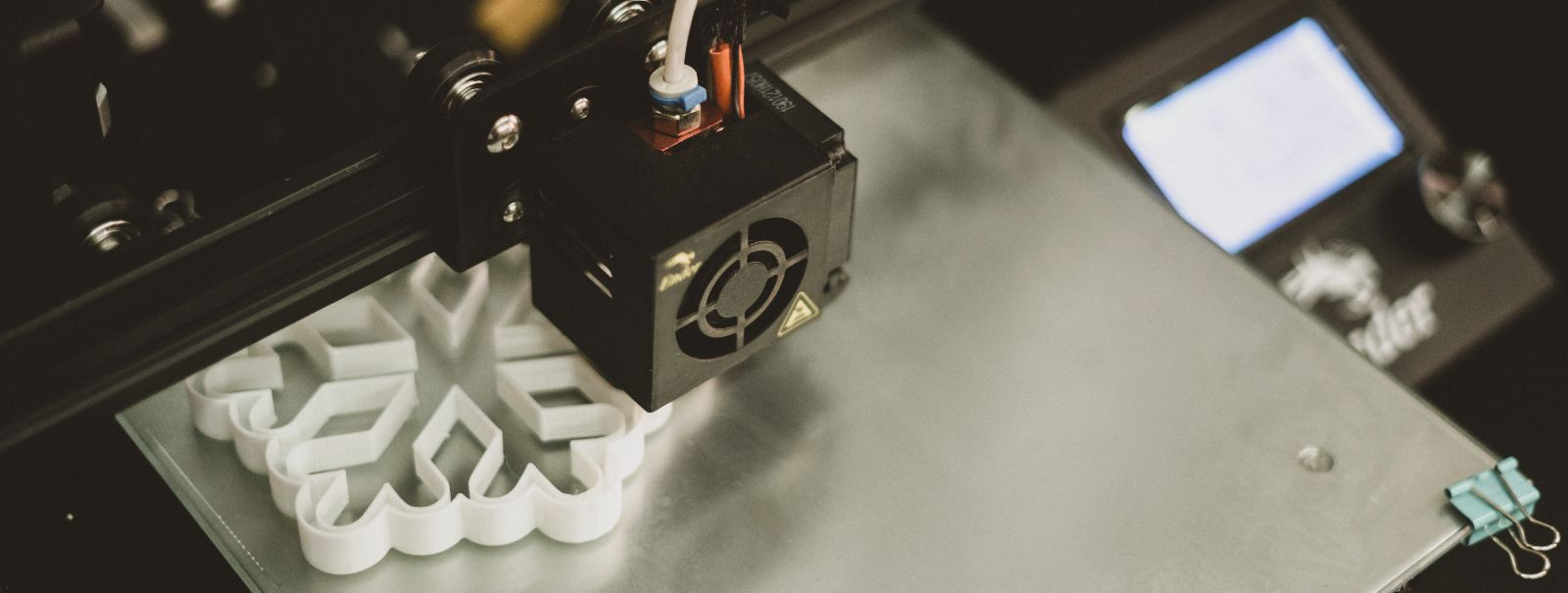

The synergy between 3D modeling and 3D printing has paved the way for rapid prototyping, allowing designers to quickly bring their digital models to life. This accelerates the development process and enables more iterative testing and refinement of designs.

4. Precision and Accuracy

3D modeling provides the tools to create designs with complex geometries and intricate details that would be difficult, if not impossible, to achieve with traditional drafting methods. This level of precision and accuracy is crucial for industries where the margin for error is minimal.

By visualizing and analyzing designs in a 3D space, errors can be detected and corrected before the manufacturing process begins, leading to better quality control and a reduction in costly mistakes.

5. Sustainable Design and Manufacturing

3D modeling allows for more efficient use of materials by optimizing design and minimizing waste. This not only reduces costs but also supports sustainability initiatives, which is increasingly important to environmentally conscious consumers and businesses.

Through 3D modeling, designers can perform lifecycle analyses to evaluate the environmental impact of their products from cradle to grave. This helps in creating more energy-efficient designs that contribute to a sustainable future.

Comments (0)