The ultimate guide to material selection for 3d printing

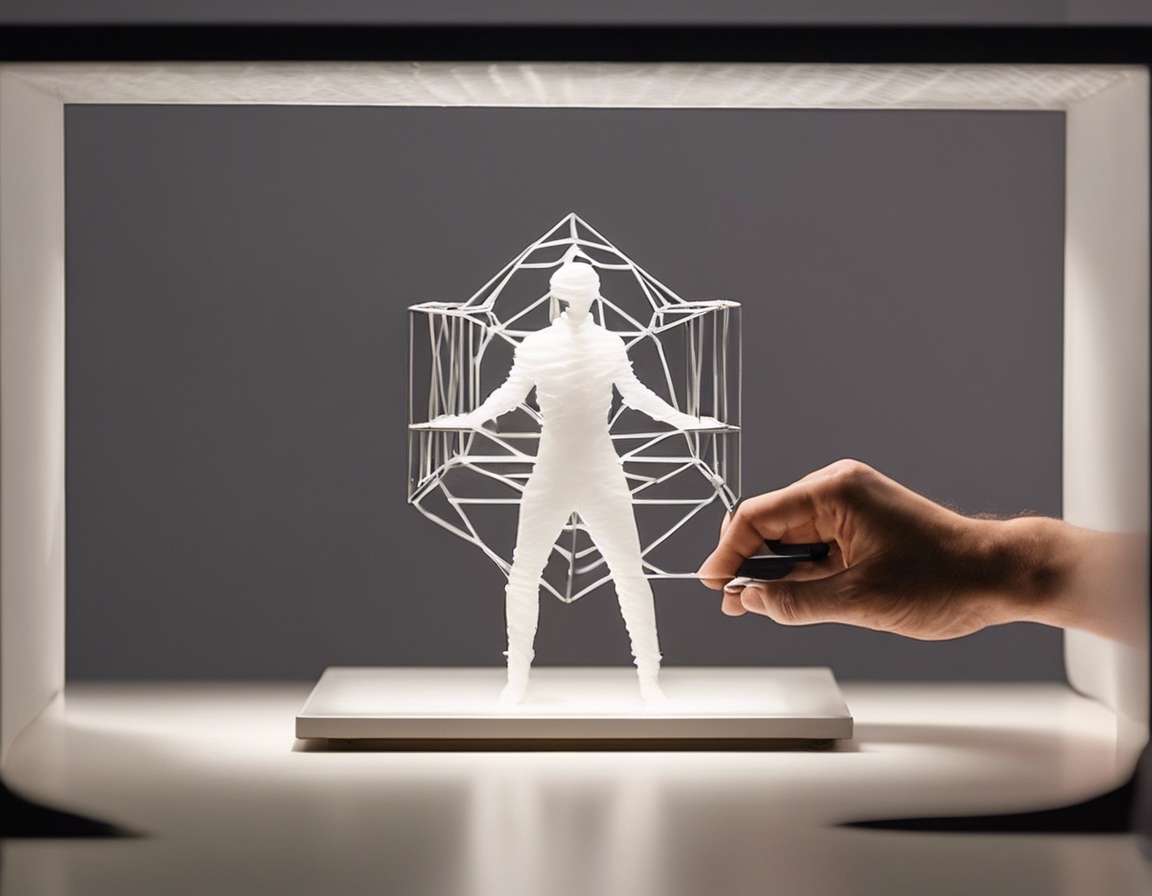

3D printing, also known as additive manufacturing, has revolutionized the way we create objects, from simple models to complex functional parts. The heart of this innovation lies in the materials used, which determine the properties and suitability of the final product. This guide will navigate through the vast landscape of 3D printing materials, helping you make informed decisions for your specific needs.

Understanding the 3D Printing Process

Before diving into materials, it's essential to understand the different 3D printing technologies available. Technologies such as Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and Metal Laser Sintering (MLS) each have unique requirements and compatibilities with different materials.

Several factors influence the choice of material for 3D printing. These include the intended application, mechanical properties, thermal properties, cost, and the specific 3D printing technology used. Understanding these factors is crucial for selecting the right material for your project.

Categories of 3D Printing Materials

Plastics are the most common materials used in 3D printing, with options ranging from PLA and ABS to advanced thermoplastics like PEEK and ULTEM. Each plastic offers a unique balance of strength, flexibility, and thermal resistance.

Metal 3D printing is growing in popularity, especially in industries like aerospace and medical. Materials such as titanium, stainless steel, and aluminum alloys are commonly used for their high strength-to-weight ratio and durability.

Ceramics offer high-temperature resistance and are often used for applications that require thermal and electrical insulation. Materials like alumina and zirconia are typical choices in this category.

Composite materials combine plastics with additives like carbon fiber or glass fiber to enhance specific properties like strength and stiffness without significantly increasing weight.

Specialty materials, including conductive inks, magnetic materials, and biocompatible resins, are tailored for niche applications that require specific functionalities.

Properties of 3D Printing Materials

The strength and durability of a material are vital for parts that will undergo stress or wear. Materials are tested for tensile, compressive, and impact strength to ensure they meet the demands of their application.

Heat resistance is crucial for parts exposed to high temperatures. Materials like PEEK and ceramics can withstand extreme temperatures, making them suitable for aerospace and automotive components.

Flexible and elastic materials like TPU and silicone can be used to create parts that need to bend or stretch, such as seals and gaskets.

For medical applications, biocompatible materials that can safely interact with the human body are essential. Resins used in SLA and SLS can be certified for medical use.

Color and aesthetics are important for consumer products and models. Many materials come in a variety of colors, and some can be post-processed for enhanced visual appeal.

Material Selection for Specific Applications

For prototyping, materials that are easy to work with and cost-effective, such as PLA and ABS, are often preferred. They provide a good balance between detail and strength.

Functional parts require materials with specific properties like high strength or thermal resistance. Metals and high-performance plastics are frequently chosen for these applications.

In the medical field, biocompatible materials that can be sterilized are necessary. Resins and metals that meet these criteria are used for implants and surgical tools.

The aerospace and automotive industries need materials that can withstand extreme conditions. Titanium and aluminum alloys are popular for their lightweight and high performance.

For consumer products, materials that are safe, durable, and aesthetically pleasing are essential. Plastics with a wide range of colors and finishes are commonly used.

Environmental Considerations in Material Selection

As environmental concerns grow, the sustainability of 3D printing materials becomes increasingly important. Materials that require less energy to produce and can be recycled or are biodegradable are preferred.

Materials like PLA are biodegradable under industrial conditions, while others like ABS can be recycled, reducing the environmental impact of 3D printing.

Compliance with environmental regulations is essential for manufacturers. Using materials that meet these standards ensures responsible production practices.

Future Trends in 3D Printing Materials

The future of 3D printing materials is bright, with ongoing research into new materials that offer improved properties and sustainability. Innovations in material science will continue to expand the possibilities of 3D printing.

Comments (0)