The future of 3d printing in sustainable manufacturing

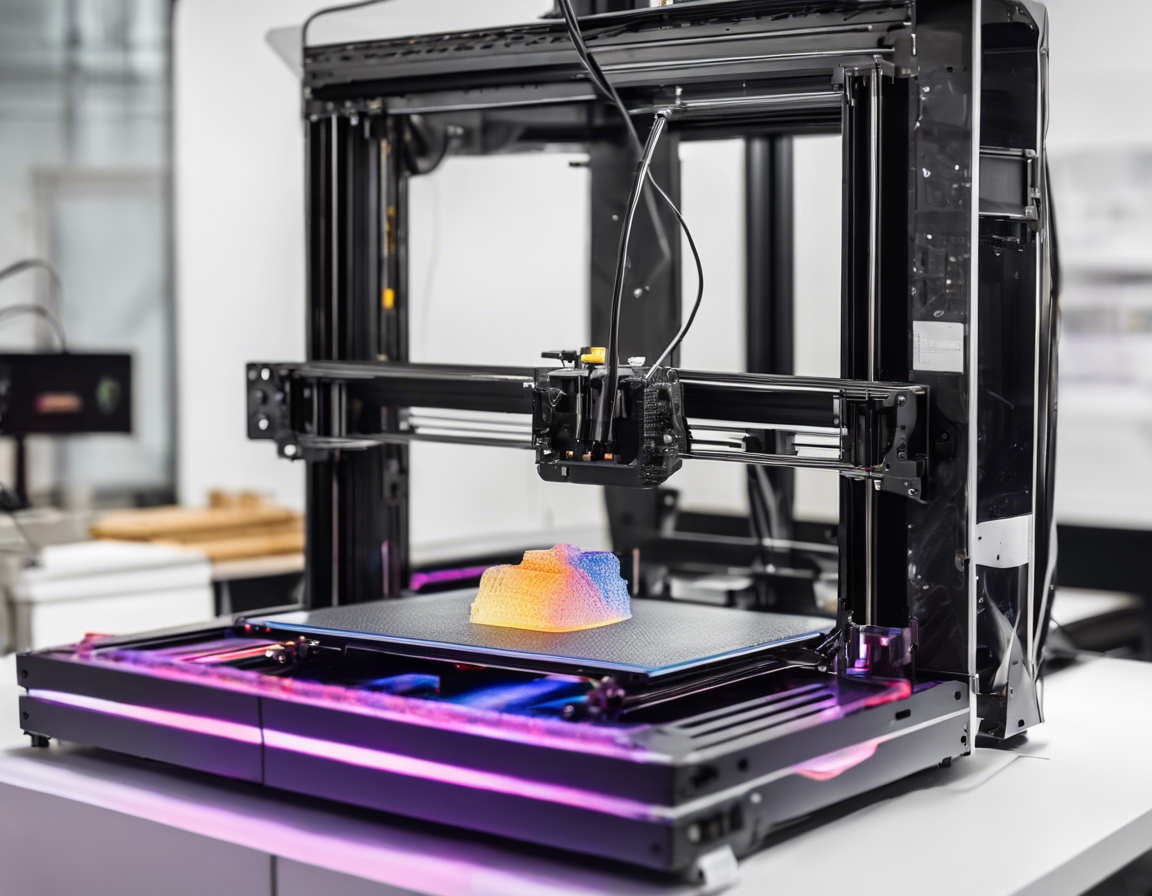

3D printing, or additive manufacturing, is a process of creating three-dimensional objects from a digital file. It involves adding material layer by layer, which is why it's considered additive, as opposed to traditional subtractive manufacturing methods that remove material. This technology has revolutionized prototyping and production across industries, offering unparalleled flexibility in design and production.

Sustainability in manufacturing is no longer a nice-to-have, but a necessity. As the global population grows and resources become scarcer, industries are under increasing pressure to reduce their environmental footprint. Sustainable manufacturing involves minimizing waste, reducing energy consumption, and using materials that are renewable or have a lower environmental impact.

The Current State of 3D Printing in Manufacturing

Traditionally, 3D printing has relied on a range of plastics and metals, some of which are not environmentally friendly. However, the industry is shifting towards more sustainable options, such as biodegradable plastics and recycled materials.

3D printing is often touted for its energy efficiency, especially when compared to traditional manufacturing processes. However, the energy consumption varies widely depending on the technology and materials used.

One of the most significant advantages of 3D printing is its potential to reduce waste. The additive process means that only the necessary material is used, unlike subtractive manufacturing which can result in significant waste. Additionally, the ability to recycle materials in 3D printing is an area of active development.

Advancements in 3D Printing for Sustainability

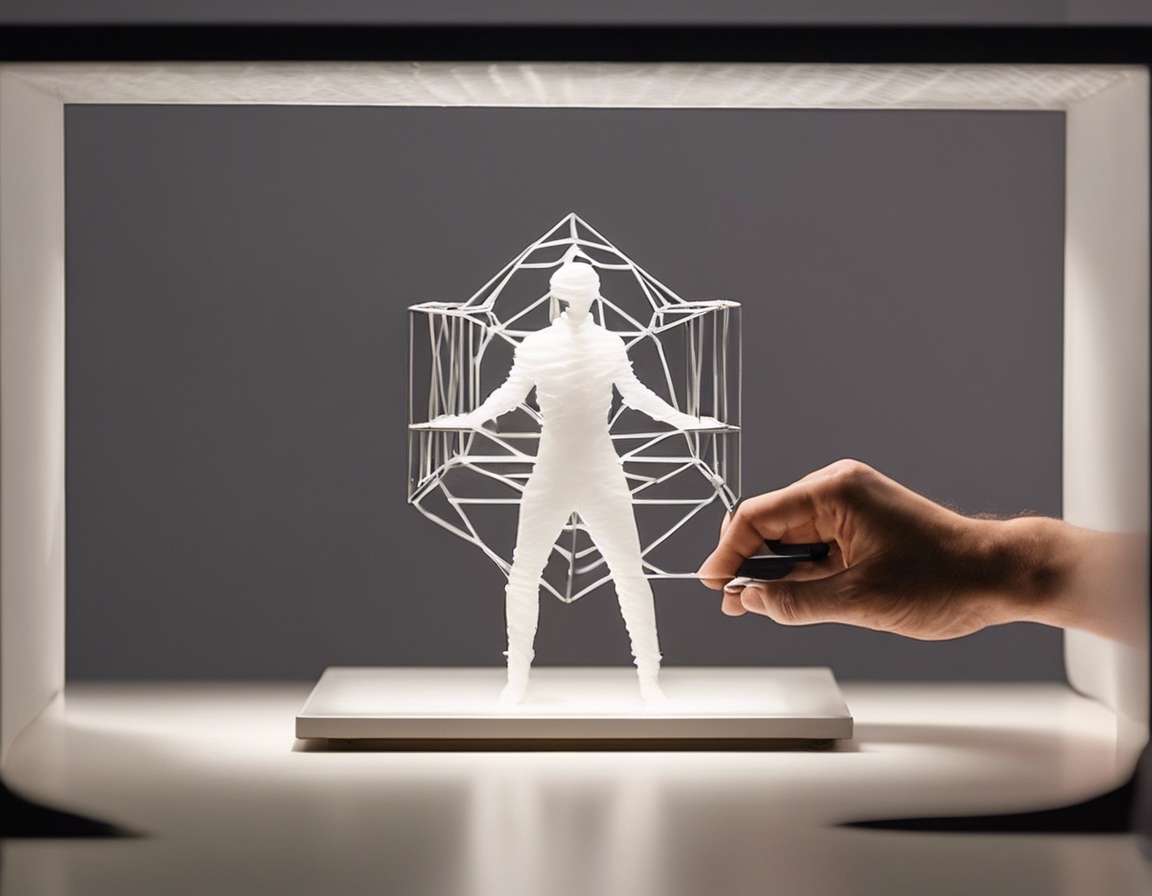

Researchers and manufacturers are constantly exploring new materials that are both high-performing and sustainable. These include biopolymers, recycled materials, and even novel composites made from agricultural waste.

As 3D printing technology advances, so does the efficiency of the printers. Newer models are designed to consume less energy, and some are even capable of using renewable energy sources.

The industry is also making strides in waste management and recycling. Innovations in this area include closed-loop recycling systems and processes that allow for the direct reuse of materials without the need for extensive processing.

Challenges and Considerations for the Future

Despite the progress, there are still technical challenges to overcome. These include improving the quality of recycled materials and developing printers that can handle a wider range of sustainable materials.

Economic and regulatory factors also play a role in the adoption of sustainable 3D printing practices. The cost of sustainable materials and technologies can be higher, and there may be a lack of regulatory incentives to encourage their use.

Scaling up sustainable 3D printing practices to meet the demands of large-scale manufacturing is another challenge. This will require not only technological advancements but also changes in industry mindsets and supply chain structures.

Looking Ahead: The Role of 3D Printing in the Circular Economy

3D printing has the potential to play a significant role in the circular economy, where products are designed for reuse, repair, and recycling. This aligns with the principles of sustainable manufacturing and can lead to a more resource-efficient production model.

For 3D printing to truly contribute to sustainable manufacturing, collaboration between industry players, policymakers, and researchers is essential. Together, they can create an ecosystem that supports innovation and sustainability in 3D printing.

Comments (0)