Company Story

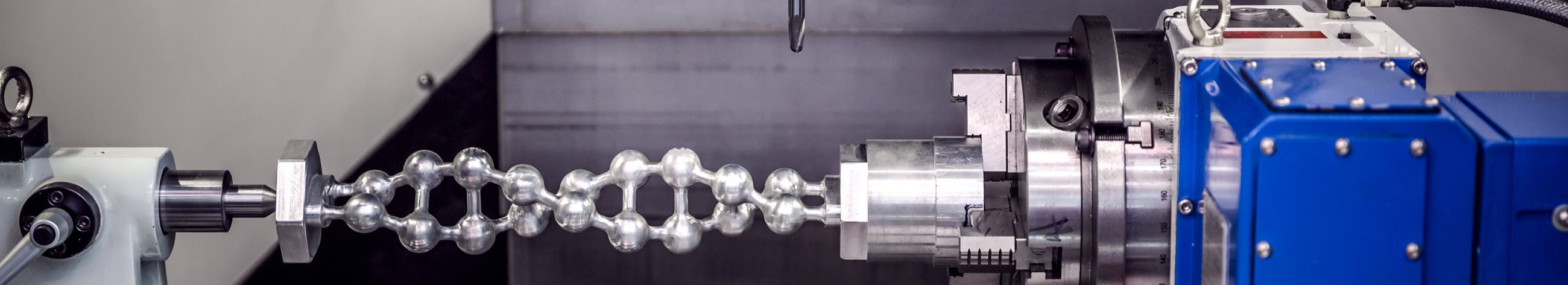

Welcome to the world of MILLPAK OÜ, where every micron matters and precision is not just a goal, it's our promise. From the heart of Tallinn, Estonia, we bring to life the art of CNC machining, turning raw metals and plastics into high-performance components that drive industries forward.

Our journey began with a simple mission: to specialize in crafting high-quality components from various metals and plastics, ensuring meticulous attention to detail in every cut and turn. This mission has been the cornerstone of our operations, guiding us to deliver products that not only meet but exceed the expectations of our discerning clientele.

At MILLPAK OÜ, we offer a comprehensive suite of services, from sourcing materials for prototype development to the final assembly and packaging of the end product. Our expertise spans across CNC turning, CNC milling, cutting workpieces, and live chairing, ensuring that every aspect of the manufacturing process is executed with the utmost precision.

Our slogan, 'Precision Crafted, Performance Delivered!', is more than just words—it's the philosophy that permeates every layer of our work. We process a wide array of materials, including mild steel, tool steel, stainless steel, alloy steel, aluminum, brass, copper, titanium, and various plastics like POM, ABS, PVC, PTFE, PMMA, polypropylene, nylon, and PET. If your project requires something unique, we're ready to meet your needs with custom solutions.

With a relentless focus on quality and flexibility, we cater to a diverse range of customer requirements, ensuring that each project is handled with the care and precision it deserves. Whether you're in need of intricate parts for aerospace, robust components for automotive, or bespoke creations for robotics, MILLPAK OÜ is your trusted partner in CNC machining.

Connect with us today and experience the difference that true craftsmanship can make. Let's turn your concepts into reality, with precision that leads to performance.

For inquiries and partnership opportunities, reach out to us at info@millpak.ee or call us at +372 512 4279. Discover how MILLPAK OÜ can elevate your projects to the next level.

Comments (0)