5 trends shaping the future of metalworking

The metalworking industry is undergoing a transformation, driven by technological advancements and evolving market demands. As we look to the future, several key trends are emerging that promise to reshape the landscape of metalworking. In this post, we will explore five significant trends that are setting the direction for the industry and how they can impact your business.

1. Advanced Materials

The development of new, high-performance alloys is enabling metalworkers to achieve unprecedented levels of strength, durability, and corrosion resistance. These materials are designed to withstand extreme conditions and are becoming essential in industries such as aerospace, automotive, and energy.

Composites and hybrid materials are gaining traction as they offer a combination of properties that cannot be found in traditional metals. By integrating different materials, manufacturers can create products with optimized thermal, electrical, and mechanical characteristics.

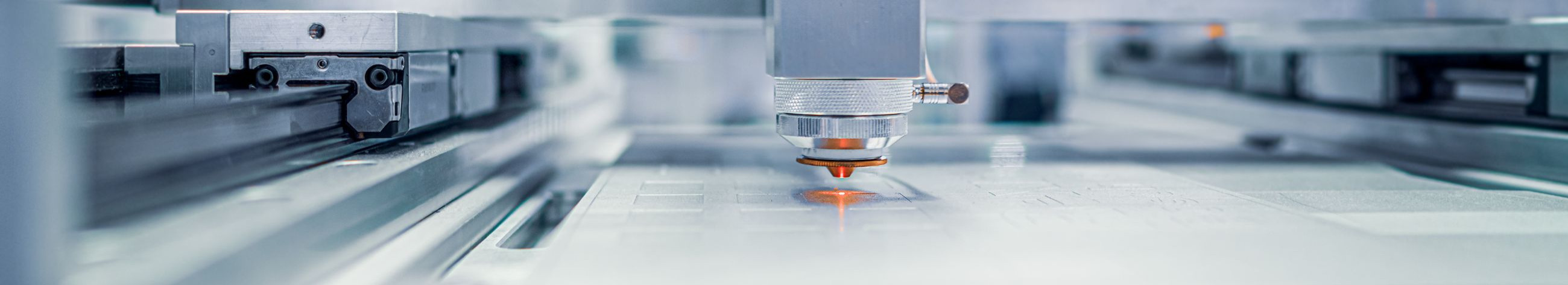

2. Precision Engineering and Micro-Manufacturing

As industries demand smaller, more complex components, micro-machining technologies are becoming increasingly important. These technologies allow for the production of parts with tight tolerances and fine details, essential for medical devices, electronics, and more.

Ultra-precision machines are pushing the boundaries of what is possible in metalworking. With the ability to achieve nanometer-level accuracy, these machines are critical for producing components that require extreme precision.

3. Automation and Robotics

Collaborative robots, or cobots, are designed to work alongside human operators, enhancing productivity and safety. They are versatile and easily reprogrammable, making them ideal for a variety of metalworking tasks.

AGVs are transforming the way materials are handled within manufacturing facilities. These mobile robots improve efficiency and reduce the risk of injury associated with manual material handling.

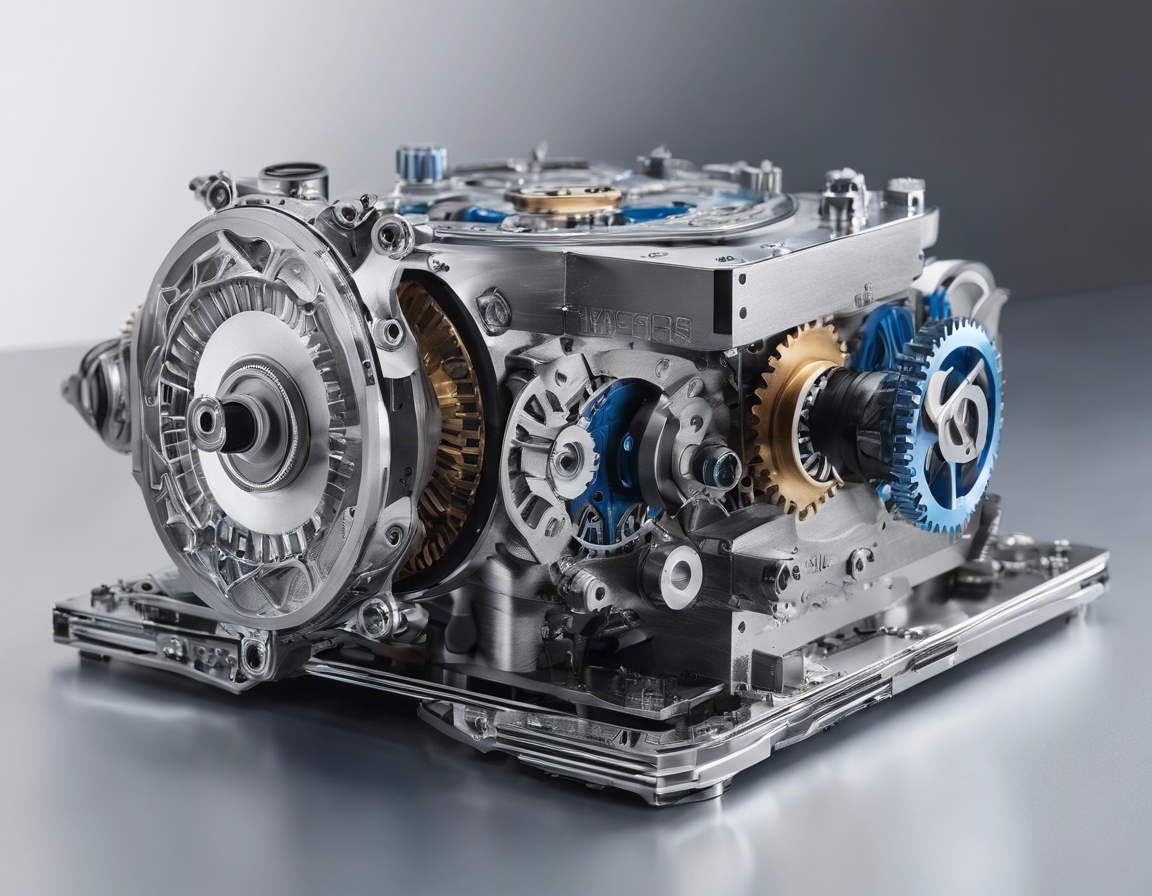

4. Additive Manufacturing and 3D Printing

Metal 3D printing is revolutionizing the way products are designed and manufactured. This technology allows for the creation of complex geometries that would be impossible or too costly to produce using traditional methods.

The ability to quickly produce customized parts is a significant advantage of additive manufacturing. It enables faster prototyping, which accelerates the development process and reduces time to market for new products.

5. Sustainable Practices and Circular Economy

Energy efficiency is becoming a priority in metalworking, with new processes and technologies being developed to reduce the environmental impact of manufacturing. This includes the adoption of renewable energy sources and the optimization of production lines for minimal energy consumption.

The circular economy is gaining momentum in the metalworking industry, with a focus on recycling and reusing materials. This approach not only conserves resources but also reduces waste and supports sustainability goals.

Kommentaarid (0)