The importance of precision in metal fabrication

Precision in metal fabrication refers to the degree of accuracy and exactness with which metal parts and components are designed, cut, formed, and assembled. It is a critical factor that determines the quality and functionality of the final product. In the realm of metalworking, precision is measured in tolerances, which are the allowable limits of variation in a physical dimension or measured value.

Precision is not just a desirable quality in metal fabrication; it is a fundamental requirement. High precision ensures that parts fit together correctly, function as intended, and can withstand the stresses and strains of their operational environment. It also minimizes material waste, reduces the need for rework, and contributes to the longevity and reliability of the product.

The Role of Precision in Various Industries

In construction and architecture, precision is paramount for the structural integrity of buildings and the aesthetic alignment of design elements. Precise metal components are essential for ensuring that structures are safe, durable, and visually appealing.

Manufacturers and machinery designers rely on precision metal parts to ensure their equipment performs optimally. Any deviation from specified dimensions can lead to machinery failure, production downtime, and safety hazards.

The aerospace and defense industries demand the highest levels of precision. Components must meet stringent standards to withstand extreme conditions and ensure the safety and security of critical missions.

Techniques and Technologies for Precision Metal Fabrication

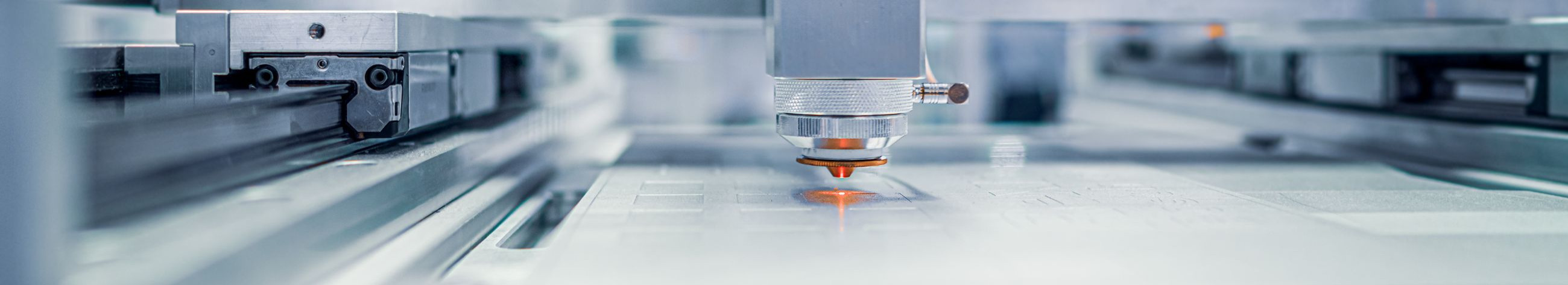

CNC machining is a cornerstone of precision metal fabrication. It uses computer-controlled machine tools to produce parts with tight tolerances and complex geometries.

Laser and waterjet cutting technologies offer high precision in cutting metal sheets and plates. These methods provide clean cuts with minimal kerf and heat-affected zones, which is crucial for maintaining the properties of the metal.

3D printing, or additive manufacturing, is revolutionizing metal fabrication by allowing for the creation of parts with intricate designs that would be impossible or cost-prohibitive to produce using traditional methods.

Challenges in Achieving Precision

Metals have unique properties that can affect precision, such as thermal expansion and contraction. Understanding these behaviors is essential for achieving accurate results.

As designs become more complex, the challenge of maintaining precision increases. Advanced software and skilled technicians are required to navigate these complexities.

Quality control is vital for precision metal fabrication. Rigorous inspection processes ensure that each part meets the required specifications.

MBH METALCUT OÜ's Commitment to Precision

At MBH METALCUT OÜ, we offer a range of precision metal fabrication services tailored to meet the exacting standards of our clients. Our state-of-the-art equipment and skilled workforce are at the forefront of delivering high-quality, precise metalwork.

We specialize in providing custom solutions that address the unique challenges of complex projects. Our team works closely with clients to ensure that every detail is accounted for and executed with precision.

Our comprehensive service extends from initial design through to final installation. We take pride in our ability to manage every step of the process, ensuring precision is maintained throughout.

Kommentaarid (0)