5 ways robotic automation is transforming manufacturing

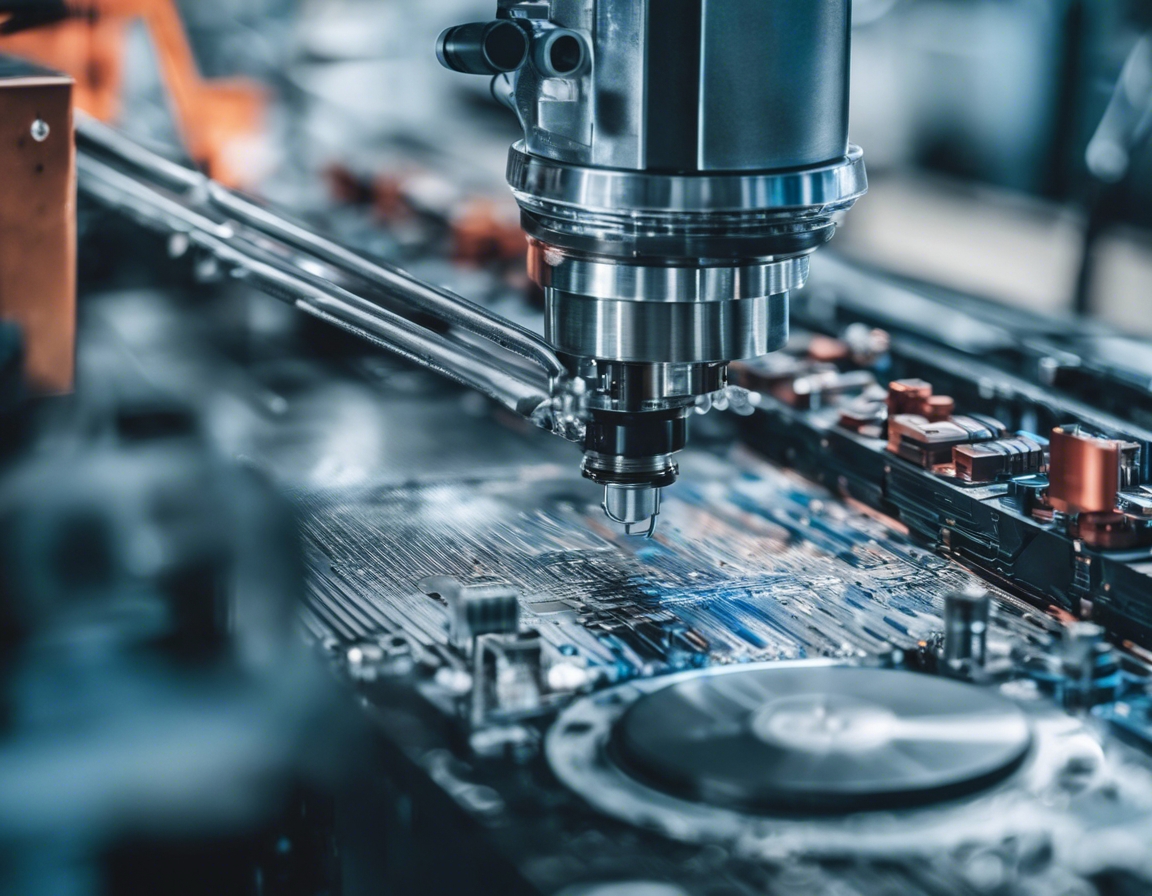

The manufacturing sector is undergoing a significant transformation, thanks to the advent of robotic automation. This technological revolution is not just changing the way products are made, but it is also reshaping the entire landscape of the industry.

Robotic automation has become increasingly prevalent in manufacturing due to its ability to enhance productivity, quality, and safety. As robots become more sophisticated, they are being integrated into various aspects of production, from assembly lines to packaging and shipping.

The impact of robotic automation on manufacturing is profound, offering a multitude of benefits that are driving the industry forward. Let's explore five key ways in which this technology is making a difference.

1. Enhanced Efficiency and Productivity

Robots can operate 24/7 without the need for breaks, vacations, or shift changes, significantly increasing the speed and continuity of manufacturing operations. This uninterrupted workflow leads to higher throughput and faster time-to-market for products.

Automation reduces the likelihood of human error, which can lead to defects or inconsistencies in the final product. By relying on precise robotic systems, manufacturers can ensure a higher level of accuracy and consistency in their operations.

2. Improved Quality and Consistency

Robots are capable of performing tasks with a level of precision that is difficult for humans to match. This precision is crucial in industries where even the slightest deviation can compromise the integrity of the product.

With robotic automation, the variability in product quality is greatly reduced. Robots can maintain the same level of performance over time, ensuring that each product meets the established quality standards.

3. Cost Savings and ROI

While the initial investment in robotic automation may be significant, the reduction in labor costs over time can lead to substantial savings. Robots can perform the work of several people and often complete tasks more quickly, reducing the need for a large workforce.

The long-term financial benefits of robotic automation are clear. Increased efficiency and productivity, coupled with lower operating costs, result in a faster return on investment and greater profitability for manufacturers.

4. Flexibility and Scalability

Modern robots are designed with flexibility in mind, capable of performing a wide range of tasks with minimal reconfiguration. This adaptability allows manufacturers to quickly respond to changes in product design or market demand.

Robotic systems can be scaled up or down to meet production demands without the need for significant changes to the manufacturing infrastructure. This scalability is essential for manufacturers looking to grow their business or adapt to seasonal fluctuations.

5. Enhanced Worker Safety and Ergonomics

Robots can take on dangerous or repetitive tasks that pose risks to human workers, such as handling hazardous materials or performing high-precision cuts. By doing so, they help reduce the incidence of workplace injuries.

By automating strenuous or monotonous tasks, robots allow human workers to focus on more engaging and creative aspects of their jobs. This not only improves worker satisfaction but also contributes to a healthier and more ergonomic work environment.

Comments (0)