Maximizing efficiency with custom robotic solutions

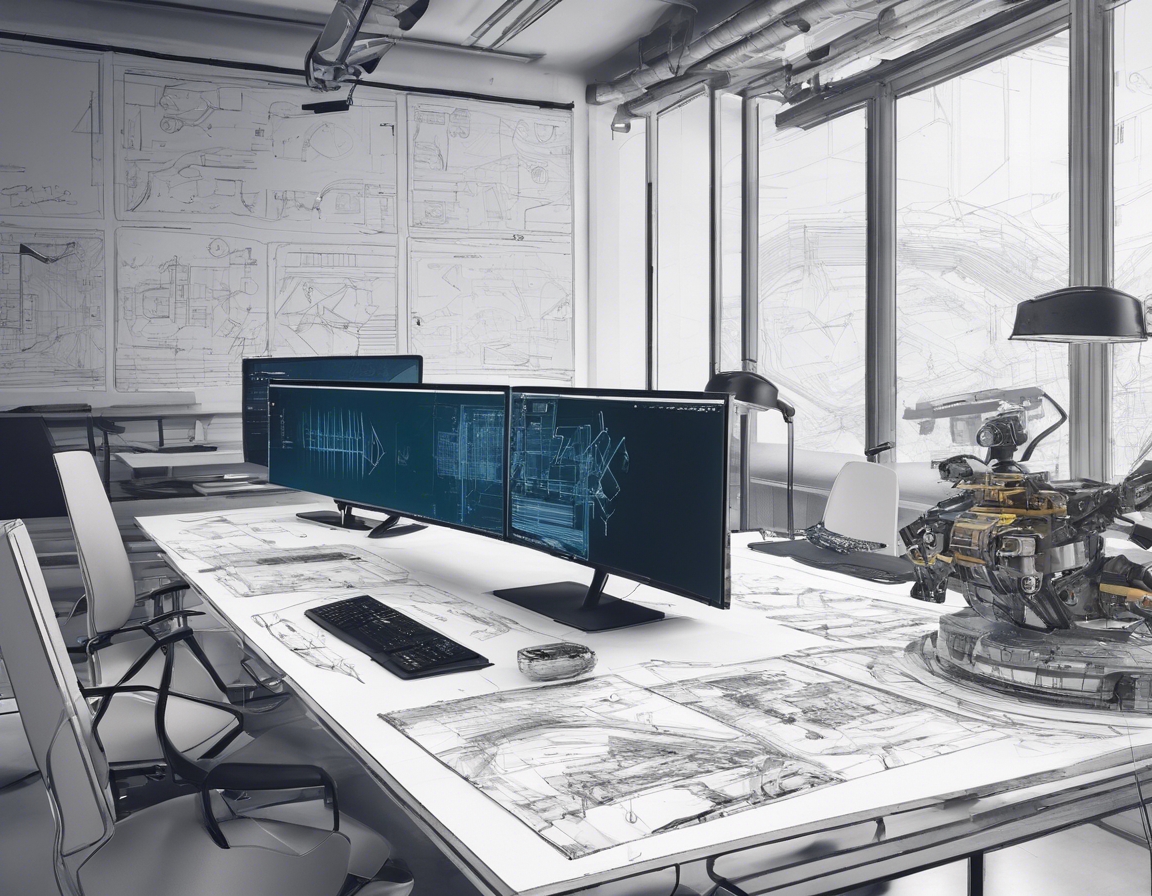

Robotics has revolutionized the manufacturing industry, offering unparalleled speed, efficiency, and precision. As the demand for customization and flexibility grows, the role of robotics becomes even more critical. Custom robotic solutions allow businesses to tailor automation to their specific needs, leading to significant improvements in production processes.

Customization in robotics involves designing and implementing systems that are specifically engineered to meet the unique requirements of a manufacturing process. This means that every aspect of the robotic system, from its design to its functionality, is created with the end-user's objectives in mind.

Benefits of Custom Robotic Solutions

Custom robotic solutions are designed to optimize production workflows, resulting in faster cycle times and higher throughput. This efficiency boost is essential for manufacturers looking to scale up production without compromising quality.

Robots are known for their precision and repeatability. Custom solutions take this a step further by integrating advanced sensors and control systems that ensure even greater accuracy, leading to superior product quality and reduced waste.

By taking over dangerous or repetitive tasks, robots can significantly reduce workplace injuries. Custom robotic solutions can be designed to operate in hazardous environments or handle materials that are unsafe for human workers.

Although the initial investment in robotic automation may be significant, the long-term savings in labor, reduced downtime, and lower error rates can result in substantial cost reductions over time.

Key Components of an Effective Robotic Solution

An effective robotic solution begins with a thorough assessment of the manufacturing needs. This includes understanding the production goals, the nature of the tasks to be automated, and the integration points within existing systems.

For a robotic solution to be truly effective, it must seamlessly integrate with a company's current manufacturing ecosystem. This includes software, machinery, and workflow processes.

As businesses grow and evolve, so must their robotic systems. Custom solutions should be designed with scalability in mind, allowing for easy expansion or reconfiguration as needed.

Robots are only as good as their uptime. Custom solutions need to be reliable and easy to maintain to ensure continuous operation and minimal disruption to production.

Steps to Implementing Custom Robotic Solutions

Finding a partner with the expertise and experience to deliver high-quality custom robotic solutions is crucial. This partner should understand the specific challenges and requirements of the industry and be able to provide comprehensive support throughout the implementation process.

The design and engineering phase is where the customization truly happens. Working closely with the chosen partner, businesses can develop a solution that is perfectly aligned with their production needs.

Before full-scale deployment, it is essential to rigorously test the robotic system to ensure it meets all performance criteria. Quality assurance processes help to identify and rectify any issues before the system goes live.

Implementing a new robotic system requires adequate training for staff to manage and maintain the technology effectively. Ongoing support from the solution provider is also important to address any future challenges.

Future Trends in Robotic Automation

The integration of AI and machine learning into robotic systems is paving the way for even smarter automation solutions that can learn and adapt over time.

Cobots are designed to work alongside humans, enhancing capabilities rather than replacing workers. These robots are becoming increasingly popular for their versatility and ease of integration.

The future of robotics lies in connectivity. With the Internet of Things (IoT), robotic systems can communicate with other devices and make data-driven decisions, further optimizing manufacturing processes.

Comments (0)