The future of robotics: trends to watch in automation

The landscape of manufacturing is undergoing a seismic shift, with robotics and automation at the forefront of this transformation. As we look to the future, it's clear that these technologies will continue to evolve, offering unprecedented opportunities for businesses to thrive in a competitive market.

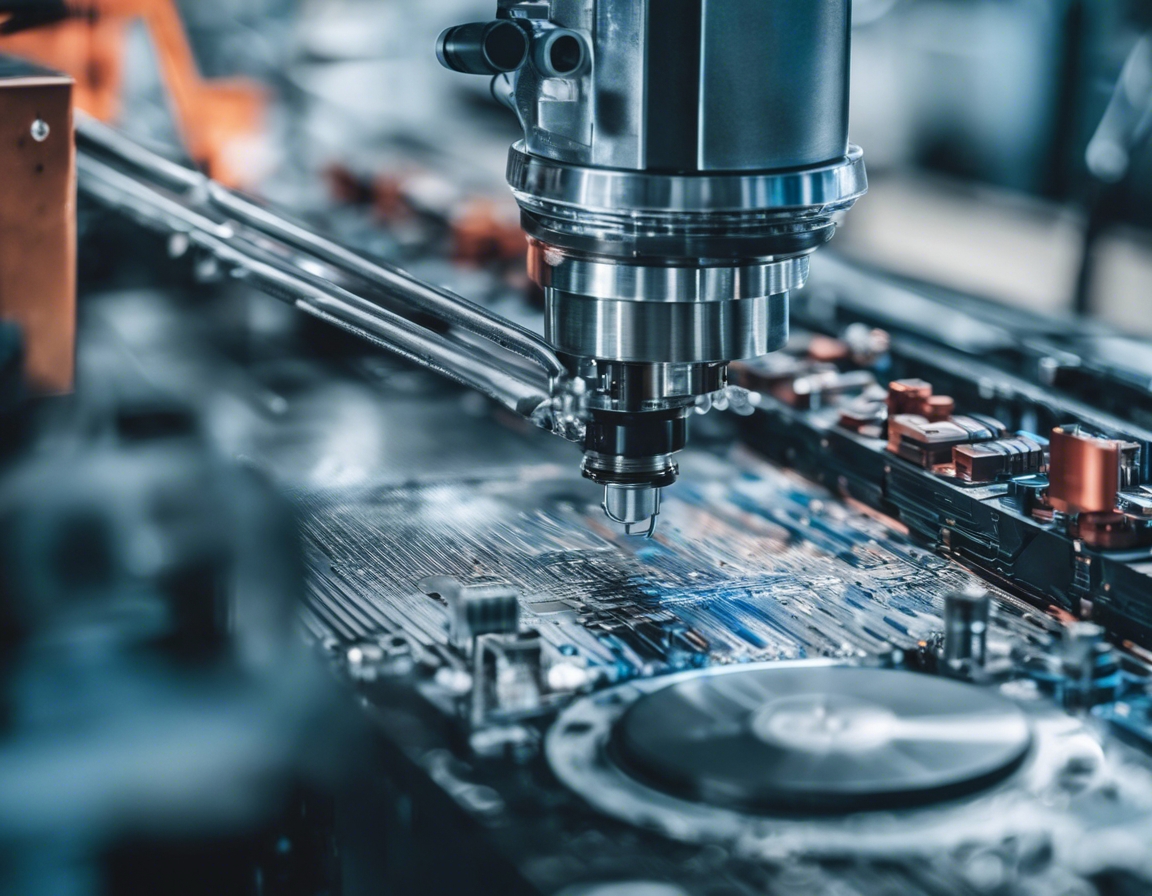

Today, robots are an integral part of the manufacturing sector, performing tasks with precision and consistency. They have become essential in various applications, from assembly lines to packaging and material handling.

Automation is not just a trend; it's a strategic imperative for businesses aiming to scale operations, improve product quality, and reduce human error.

Emerging Trends in Robotics

Cobots are designed to work alongside humans, enhancing productivity and flexibility in the workplace. They are becoming increasingly sophisticated, with capabilities that allow them to adapt to a variety of tasks.

AI and machine learning are revolutionizing robotics, enabling machines to learn from experience, improve over time, and make autonomous decisions.

Robots equipped with advanced vision and sensory systems can navigate complex environments and perform intricate tasks that were once thought impossible for machines.

RaaS models allow businesses to access robotic solutions through a subscription-based service, reducing the need for large upfront investments.

The development of mobile and autonomous robots is expanding the boundaries of where and how robots can be utilized, particularly in logistics and inventory management.

Impact of Robotics on Manufacturing

Robots are key drivers of productivity, enabling faster production times and higher throughput with minimal downtime.

By taking on dangerous or repetitive tasks, robots are improving safety conditions for human workers, reducing the risk of accidents and injuries.

Robotics technology is paving the way for mass customization, allowing manufacturers to offer personalized products without sacrificing efficiency.

Challenges and Considerations

Integrating new robotic technologies with existing manufacturing systems can be complex, requiring careful planning and execution.

The rise of robotics is creating a demand for a skilled workforce capable of operating and maintaining these advanced systems.

While the long-term benefits are clear, the initial cost and investment in robotics can be a barrier for some businesses.

As robotics become more prevalent, there will be increased scrutiny on regulatory compliance and the ethical implications of automation.

Comments (0)